RK has two operational groups: Medical Device Contract Manufacturingand Machine Tool Development and Manufacture. We have the knowledge and experience to take your product / design from inception to final packaging. Our certified quality inspectors monitor every process, so you can be sure your product will be defect free. We have the capability and capacity to assist you in completing all of your assembly needs.

At RK Manufacturing, we pride ourselves on having the best customer service in the industry. Our knowledgeable staff is always ready to assist you. Quick response time and attention to quality make us an invaluable supplier to our customers. Our flexible manufacturing capabilities allow us to produce large and small quantities quickly and cost efficiently.

- Design and Development Assistance

- Prototyping

- Custom Manufacturing

- Short lead times

- Orders sizes from 1 to 1,000,000

- Complete suture and medical device assembly

- Clean room/White room environments

- Final sterilization of packaged product

- Full lot control and traceability

- Sterilization validation and processing

- Validation protocol development, testing and reports

- Complete work order history

- Worldwide shipping

The Machine Tool Development and Manufacturing Group offers:

- Tooling, fixture design and fabrication

- Prototyping

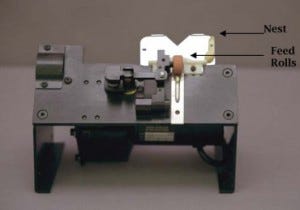

- Precision machined suture processing equipment

- Comprehensive Machining services

- Worldwide shipping

Originally published at rkmcorp.com.